CUSTOM PRODUCTION

PRODUCTS PRODUCED TO SPECIFIC CUSTOMER NEEDS

We work to understand the needs of food manufacturers, customizing our production process to deliver Assured, Traceable food ingredients backed by Technology.

ASSURED – IT STARTS AT THE FARM

Location

Our growing location in the Saskatchewan Palliser Triangle is some of the most productive land in the world. Nutrient rich soil and a semiarid climate allows for the production of pulse, cereal, oil and specialty crops. Dispersing production acres in this area reduces environmental risk providing consistent supply of our food ingredient products. At BloK Ingredients we use this resource respectively, contracting with Professional Growers following protocols to produce sustainable ingredients.

Growers

BloK Ingredients contracts with dedicated Professional Growers utilizing generations of experience and modern practices to produce our products. Years into developing and vetting our grower network has assisted in consistent product quality and quantity. Our growers have ongoing commitments including:

- Excellent farming practices

- Reduced carbon footprint

- Digital production records

- Land free of noxious weeds or potential contaminants

Production Controls

Our production assurance program can be customized for food manufactures requirements. These are communicated to our Professional Growers ensuring quality, residue, and sustainability expectations are achieved. BloK Ingredients has ongoing grower commitments including:

- BloK Ingredients production assurance program training

- BloK Ingredients production planning

- BloK Ingredients onsite inspections

Traceability is only achieved by aligning effective production practices within precise designed controls

Production Tools

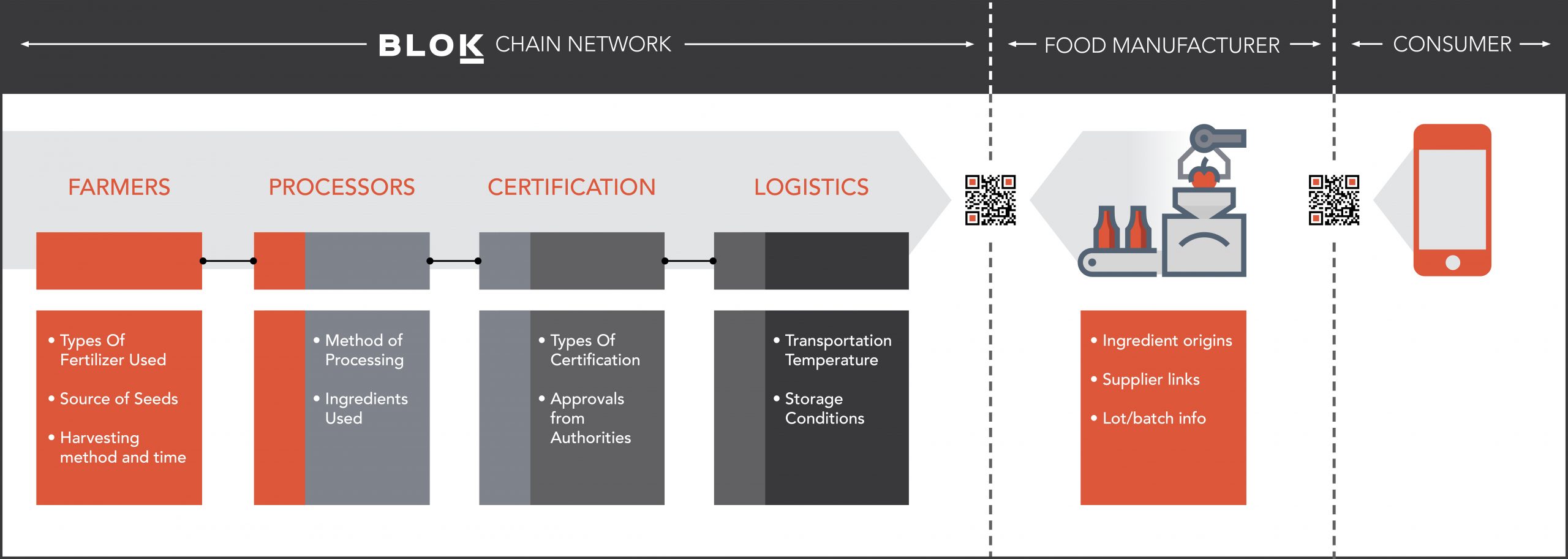

TRACEABILITY – FIELD TO FORK

WE ARE THE KEY

Contract with BloK Ingredients specific production fields, our goal is to create efficiencies, enhance food safety, and increase consumer confidence expanding market opportunities and revenue for food manufacturers.

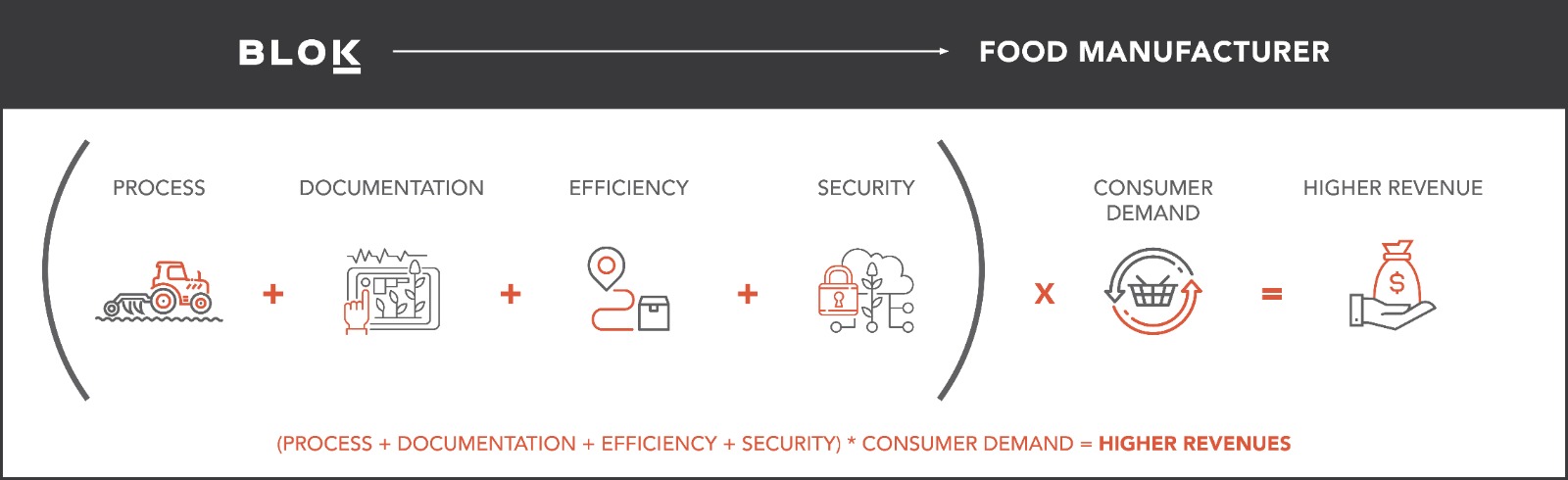

The Equation

Process

BloK ingredients production assurance program is the first part of the equation, what are the expectations of the grower, manufacturer and consumer.

Documentation

Developing digital documentation systems around legacy accreditations like the Canadian Identity Preserved Recognition System (CIPRS) ensures process controls deliver the right product to its consumer.

Efficiency

Integrating multiple physical and digital processes, within an accessible enterprise resource planning software, accommodates efficient transfer of ingredient products and their related data.

Security

Food safety and security is always a concern, our development of Hazard Analysis Critical Control Point (HACCP) system is our commitment to food manufactures and consumers alike.

Consumer Demand

Food manufacturers have the best understanding of end consumer demand. BloK Ingredients strives to accommodate not define this demand. By being transparent in production methods we allow food manufacturers the ability to narrow down and query data relevant to the consumer.

Higher Revenue

Consumers increasingly want to know the origin of the food they eat. Being able to offer this “Farm to Fork” information on food ingredients and food products can help the agriculture and food industries gain access to new markets and drive revenue.

Processing Tools

TECHNOLOGY – OUR FUTURE

Why Blockchain?

Focusing on data collection, we recognize the need to be transparent and compliant. Our production and processing data can be placed on Blockchain Hyperledger, securing the data while providing public and private access. We work with food processors to implement blockchain technology to generate new value for their products – creating efficiencies in data transfer and sharing and enhancing the end consumer’s experience with products.

Benefits of Blockchain

- Auditability: once recorded in a blockchain, information is fixed and can be referenced at any point in the future, allowing future parties to verify that the information has not been tampered with.

- Data Management: blockchains can intake a wide variety of information rather than be restricted to a particular format, such as data from an inventory management system, batch or lot records for unique identification, or GPS data for location information. As a result, blockchain systems can serve as hub between different software platforms that may need to exchange information.

- Transparency: allows for increased trust between business parties, as they can now confirm the validity and authenticity of information posted on the blockchain

The Origins of Blockchain